Full digitalization of factory operations

EOS-branded MES solution based on Microsoft platform

Why EOS Power MES?

⚙️ Do you want to make your factory's production processes more efficient?

🔎 Would you like to reduce costs and inefficiencies related to the lack of control of production facilities?

⏱️ Do you want to collect process quality data and analyze performances?

What is it?

Pillars

Analytics

Features

Highlights

AI

Cloud

Communication

Manufacturing Execution System

EOS Power MES: manufacturing process management app

A MES (Manufacturing Execution System) is a system that manages production execution within a manufacturing company. The main goal of a MES is to provide effective supervising and control of production activities in real time, improving the efficiency and quality of the manufacturing process.

To sum up, a MES system helps companies improve production efficiency and quality by reducing manufacturing time, while minimizing errors and optimizing the use of available resources.

EOS Power MES: its pillars

- Product structure management - cycles, bills of materials production orders etc.

- Resource management - employees, machines, departments etc.

- Dispatching of manufacturing's plan

- Recording of employees' hours - time and cost

- Integration with machines - recording of useful data for cost tracking and servicing

- Maintenance management - routine, non-routine for failure, predictive

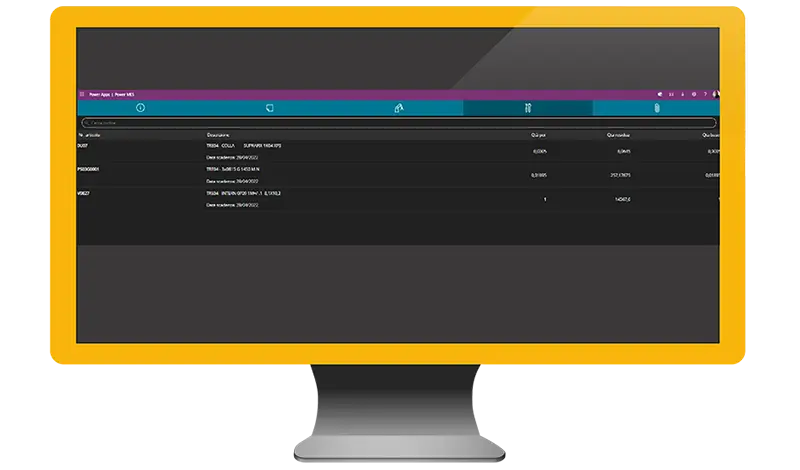

- Gathering of process quality data - which are detected by machines or by the operator during manufacturing

- Traceability

- Performances analysis

Azure IoT, Azure Stream Analytics and Power BI

Data gathering and analisys

EOS Power MES integrates with Azure IoT and Azure Stream Analytics to efficiently gather and manage data from devices. Azure IoT allows you to manage communication between different devices and applications that use the data, which are generated continuously by the devices.

EOS Power MES also makes available indicators based on Power BI, that provide information about the performance of a department or of a machine in terms of availability, continuity and product quality.

Azure IoT: devices connecting and monitoring ▼

Using Azure IoT services, EOS Power MES allows you to manage communication between different devices and applications that use the data, which are generated continuously by the devices.

In this way, gathering and analyzing data from the devices becomes an easier task, which allows you to:

- make faster decisions

- preserve production equipment

- boost efficiency

- increase flexibility

Power BI: visualizing data and making decisions ▼

Power BI turns business data into advanced visual elements. It provides clear reports and dashboards that help you better understand the data.

EOS Power MES: main features

Highlights

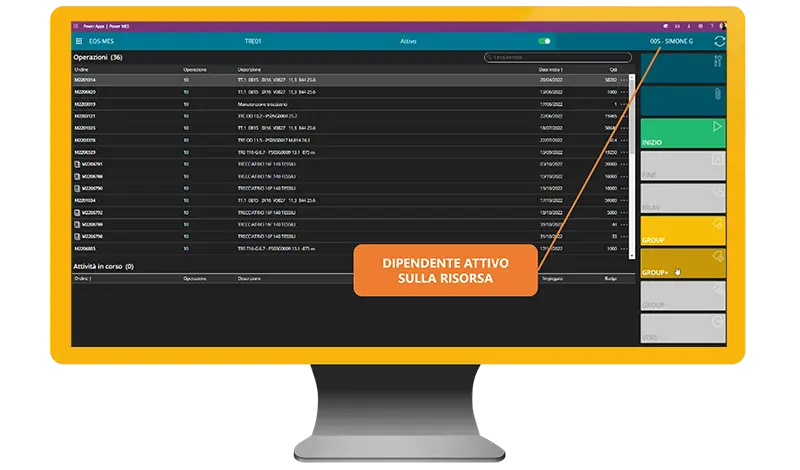

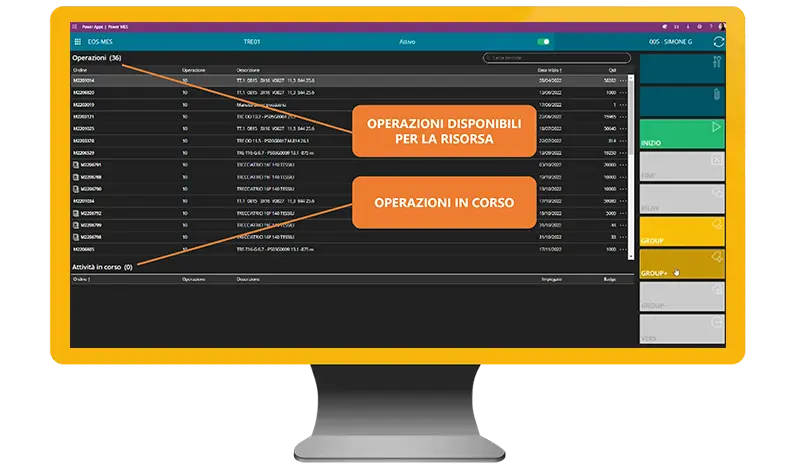

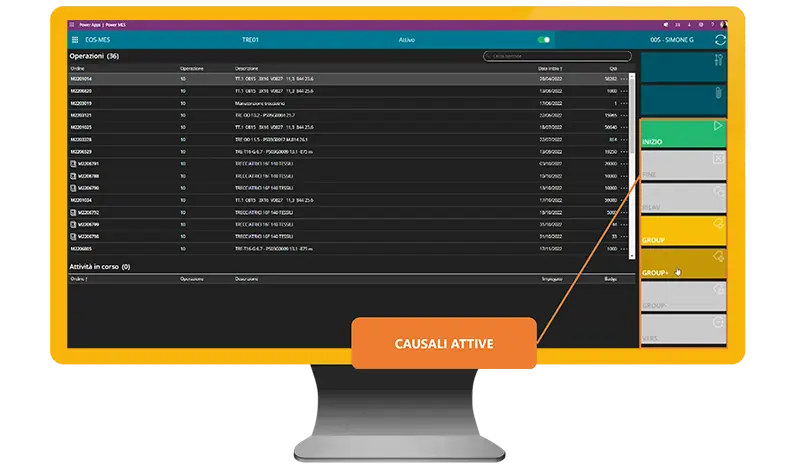

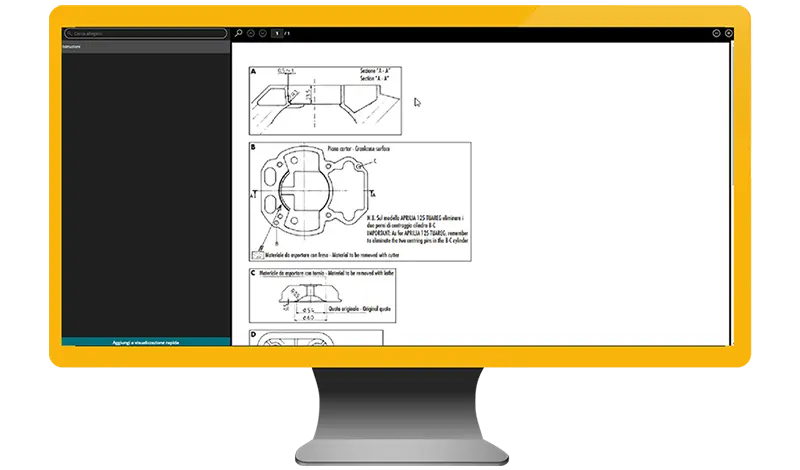

Production Panel

After the login into the Production Panel in the app, the operators can see the tasks to be performed (or already performed) and the possible causes (e.g., start or end of processing).

DETAILED ANALYSIS

Therefore, the operators can see the details of an operation, view/add notes, view equipment, components and even multimedia content (e.g., movies), consult work instructions (e.g., assembly). It's even possible to enter quality control results.

Azure Machine Learning

Artificial intelligence and predictive maintenance

The integration with Azure Machine Learning services makes it possible to manage and to deliver artificial intelligence models, and to monitor their entire lifecycle. EOS Power MES provides two models that are applied to the maintenance of production facilities:

Anomaly Detection ▼

The anomaly detection model allows to examine specific pieces of data from devices, and detect rare events that may be anomalous because they differ from an established pattern of behavior and then report them. Through the observation of anomalous data, it is possible to do preventive activities on possible failures.

Predictive Maintenance ▼

This machine learning model enables information about the status, health, and remaining life of a device. Which are the benefits?

- Decrease in detentions

- Equipment's preserving

- Boost in quality

- Scheduling of spare parts

- Increased safety

continuous digital evolution

Continuous Update in Cloud

Thanks to the Cloud, EOS Power MES is costantly updated, with the aim of ensuring an ever more feature-rich platform and of embracing the ongoing digital evolution of the entire Microsoft ecosystem.

Through the continuous update, customers have access to new features and innovations, with guaranteed continuity of service.

Why should you embrace a cloud-based factory digital solution? ▼

- Scalability:

- You can start with a small implementation

- The validity of the solution is demonstrated

- Growing along with the company growth

- Less risks and costs in the solution's delivery, more speed

- Combination of multiple software components into one optimized, scalable and safe cloud-solution

- Simplifying and decreasing the cost of user training

integration with Teams, Sharepoint and Power Automate

Communication and collaboration

By integrating with Power Automate, Teams and SharePoint, EOS Power MES allows you to create automated workflows, share tasks, organize documents and information.

With the power of integration and data intelligence, EOS Power MES transforms manufacturing into an intelligent, effective and efficient digital system.